Heavy-Duty Linear Servo (Position Control, 12-24V, 225lb Thrust, 0.3"/sec, 8" Stroke)

SKU:While a linear servo may appear similar to a linear actuator, it functions quite differently. A linear servo responds to a PWM signal - to achieve the same results, a linear actuator would require a motor controller with a feedback loop capable of responding to a PWM signal. The linear servo is designed to simply plug into a servo controller and run without any additional tuning or wiring from the end-user. The advanced internal circuit board is able to accept a PWM signal from about any servo controller which means that you can operate this unit from a wired servo controller such as our Dual Servo Driver or Servo Recorder, a wireless transmitter and receiver or even a microcontroller such as an Arduino. The closed-loop feedback allows the linear servo to be driven to any location within its stroke range by simply sending the corresponding signal to the servo from the servo controller. The internal circuit board is able to check the current position reading from the internal potentiometer and accurately control the position of the extension tube by supplying power to the motor until the called-for position has been reached.

The male XT30 connector requires a 12V input with a minimum of 5A in order to power the linear servo. When power is supplied to the XT30 connector, it will automatically feed 5V (500mA) down through the twisted lead that plugs into your servo controller so that both the linear servo and the servo controller can run off the same power source. For tips on powering a linear servo see the tech tips section below.

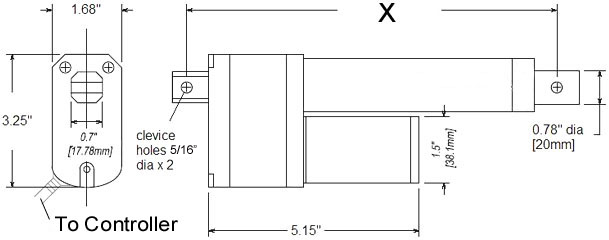

Linear servos can be used in place of pneumatics and hydraulics. The ACME screw that drives the extension tube provides efficient linear thrust and allows the linear servo to handle immense static loads without being back-driven even with power removed. The metal construction of the linear servo provides tremendous durability and reliability. Linear servos are able to operate in any orientation and provide equal force in both the pulling and pushing directions. The mounting clevis nearest the motor is fixed but the mounting clevis on the extension tube is able to be rotated if your application requires the holes to be oriented differently. Mounting holes are 5/16" diameter.

|

| |||||||||

Tech Tips:

Linear Servo Power Tips

- If your controller is already powered by another source, we recommend that you disconnect the red wire from the twisted servo lead in order to disable the BEC. Servo controllers should never be powered from multiple sources at once.

- If the combined current consumption of your servo controller and other servos that might be plugged in is greater than 500mA, disconnect the red wire from the twisted lead in order to disable the BEC and run the servo controller on a separate power source.

- We do not recommend that the power source be part of a charging circuit, such as a vehicle with an alternator or generator supplying power to the battery while running. Consider running the linear servo off of a separate battery so that it does not experience fluctuations in voltage from a charging circuit.

Specs

| Stroke | 8" |

|---|---|

| Pulse Amplitude | 3.3-5V |

| Operating Temperature | -20°C to +60°C |

| Deadband Width | 8µs |

| Motor Type | 3 Pole Ferrite |

| Feedback Style | 10KΩ Potentiometer |

| Gear Material | Metal Gear Train, Nylon Pinion |

| Wire Length | Servo Lead: 12.0”, Power Input: 6.0" |

| Weight | 45.1 oz |

| Wire Gauge | Servo Lead: 22awg, Power Input: 14awg |

| Voltage Range (Nominal) | 12 - 24V |

| Voltage Range (Maximum) | 11 - 30V |

| Speed (No Load)* | 0.30” per second |

| Gearbox Style | Straight Cut Spur |

| Connector Type | Servo Lead: Male Servo Connector, Power Input: XT30 Connector [FH-MC] |

| Gear Ratio | 40:1 |

| Speed (Max Load)* | 0.20” per second |

| Dynamic Thrust* | 225 lbs |

| Static Load | 500 lbs |

| Current Drain (No-Load)* | 1A |

| Current Drain (Max Load)* | 4.5A |

| Potentiometer Tolerance | ± 5% |

| Feedback Density | 1.25KΩ / inch |

| IP Rating | IP53 |

| Duty Cycle | 25% (25% on, 75% off) |

| Lead Screw Type | 3mm pitch, single thread |

| Potentiometer Linearity | ± 0.25% |

| PWM Signal (Fully Retracted) | 1900µs |

| PWM Signal (Fully Extended) | 1100µs |

| Current Drain (Idle)* | 25mA |

| Previous SKU | HDLS-8-30-12V |